Processing Capacity: depending on specific situation

Processed Materials: Copper, zinc, nickel, gold and other nonferrous metals, coarse and fine separation of nonmetals like coal, fluorite and talc.

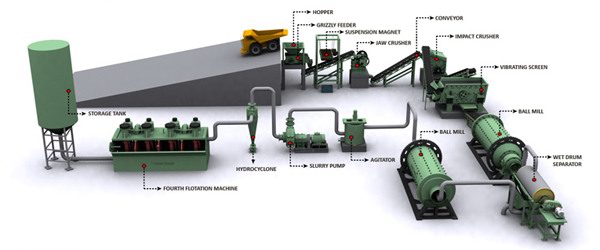

Main Equipment : Jaw crusher, hammer crusher, ball mill, classifier, magnetic separator, flotation cell, thickener, dryer, etc.

Ore beneficiation line or ore processing plant consists of jaw crusher, hammer crusher, ball mill, classifier, flotation machine, concentrator, dryer mine feeder, hoist and conveyor. It has unique features such as high efficiency, low energy consumption and large capacity.

Fote ore beneficiation plant can be divided into iron ore processing plant, copper ore processing plant, gold ore concentration plant, silver ore beneficiaiton plant, nickel ore processing plant, tin ore benefication plant, lead ore benefication plant, manganese ore benefication plant, zinc ore benefication plant, titanium ore benefication plant, tungsten ore benefication plant, etc. All of these ore benefication plant are of high quality and reasonable price.

1. Re-beneficiation method

Re- beneficiation method is sorting minerals based on their differences of relative densities (usually called gravity). Mineral particles of different densities in the moving medium (water, air and heavy liquid) are affected by various mechanical forces, which result in a loose stratification and separation conditions so that mineral particles of different densities can be separated.

2. Flotation beneficiation method

Flotation method separates minerals based on their differences between physical and chemical properties. After pharmaceutical treatment by flotation, useful minerals will selectively attach to bubbles to reach sorting purposes. Flotation process is suitable for non-ferrous metal ores, such as copper, lead, zinc, sulfur and molybdenum as well as some ferrous metals, precious metals and a number of non-metallic minerals such as graphite ore and apatite.

3. Magnetic beneficiation method

Mgnetic beneficiaiton method separates minerals depends on different forces they received in magnetic field of the magnetic separator. It is mainly used for sorting ferrous metal ores (iron, manganese, chromium); as well as non-ferrous metal and rare metal ores.

4. Electric beneficiation method

Electric beneficiation method sort minerals according to their different conductivities. Because of their different conductivities, minerals will receive different static forces when they pass the high-voltage electric field, so minerals can be separated. Electric beneficiation method is suitable for sorting rare metals, non-ferrous metals and non-metallic ores. Recently, it is mainly used for separating and concentrating of coarse minerals such as scheelite, cassiterite, tantalum and niobium and zircon ores.

FTM has equipment installed throughout the world in areas

such as South Africa, Middle East, West Asia,India, Philippines, Western Europe, Southeastern Asia.

NOTE: You can also send a message to us by this email info@sinoftm.com , we will reply to you within 24 hours. Now tell us your needs, there will be more favorable prices!