Email us: info@sinoftm.com

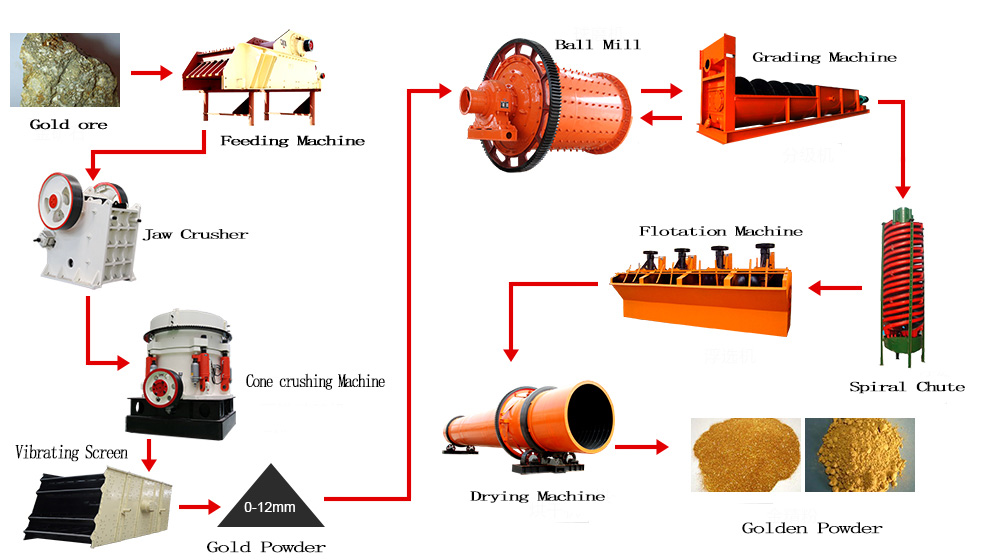

The ball mill is the key equipment for crushing the material after it is broken. This type of grinder is fitted with a certain number of steel balls in its barrel for abrasive media. Ball mill in operation, Ball Mill steel Ball in the role of gravity, and constantly hit the mineral, continuous circulation, grinding to qualified finished products.

It is widely used in cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal beneficiation and glass ceramics, and other industries, the dry or wet grinding of a variety of ores and other abrasive materials. The ball mill is suitable for grinding a variety of ores and other materials and is widely used in mineral processing, building materials and chemical industries. It can be divided into dry and wet grinding methods. According to different ways of ore discharge, it can be divided into grid type and overflow type. At present, the latest type of energy-saving ball mill has emerged, and it is most welcomed by users. It is an upgraded product of ball mills and is commonly found in large and medium-sized ore dressing production lines.

Ball Mill is able to process a lot of materials, and with the advent of new materials, beneficiation technology progress, the use of ball mill performance in the continuous improvement, processing effect is also significantly improved, the ball mill can be processed barite, slime, potash feldspar, tungsten carbide, copper, slag, hematite, lime, gold ore, aluminum powder, high aluminum porcelain, iron powder, Fluorite ore, aluminum powder paste, steel slag, quartz sand, sulfuric acid slag, barite, clinker, bauxite, ceramsite sand, etc. dozens of or even hundreds of ores, widely used in cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal mineral processing and glass ceramics and other production industries.

1. More energy-saving: 30%, the traditional ball mill using sliding bearings, a new ball mill using rolling bearings, has a good starting performance and load capacity, lower energy consumption.

2. More environmental protection: Seal Well, the ball mill uses the special seal device, isolates the air pollution product element, also avoids the dust to enter the air, guarantees the neat working environment.

3. More wear-resistant: The material is advanced, the wearing parts of the ball mill are imported wear-resistant materials, new structural liners, optimized gear design, improve the wear resistance and compression resistance of the whole machine.

4 better use: simple structure, the whole structure is simpler, easier to operate, the body is strong, stable operation, users can quickly get started.

5. More convenient: automatic operation, the ball mill has a higher level of automation, can achieve unmanned operation, can be continuous feeding, continuous operation, improve production, to meet the requirements of large-scale industrial production.

Prev: Introduction of Rod Mill Machine

Next: Last